Side-draft Carburettor Soft Mount Installation

Correctly fitted "soft mounts" are an integral part of installing dual throat sidedraft carburettors onto nearly all applications. Manufacturers such as Alfa Romeo who extensively fitted side-draft Weber DCOE and Dellorto DHLA carburettors recognised this, and devised their own mounting system specific to Alfa manifolds.

With the introduction of aftermarket manifolds for side-draft carburettors in the 1970s, universal soft mount systems were devised.

There are three main funtions the soft mount performs;

1 - Seals the carburettor to the manifold. Lynx soft mounts utilise Nitrile O-rings which are compatible with most fuels including E85.

2 - Limits engine vibrations being transmitted to the carburettor. Engine vibrations and resonance can cause the fuel in the float bowl to airate (or "froth"). This causes a lean air/fuel mixture fault. The vibration puts added stress on the float, and also reduces the ability of the needle valve to meter the fuel properly. Needle valves have a drastically reduced operational life without soft mounts and tend to leak after short periods of time.

3 - Reduces stress on the manifold and carburettor. It is not uncommon for side-draft carburettors to hang 350mm or more from the cylinder head face. This puts an incredible amount of stress on the inlet manifold itself. Cracked/broken manifolds are the result, as are broken carburettors.

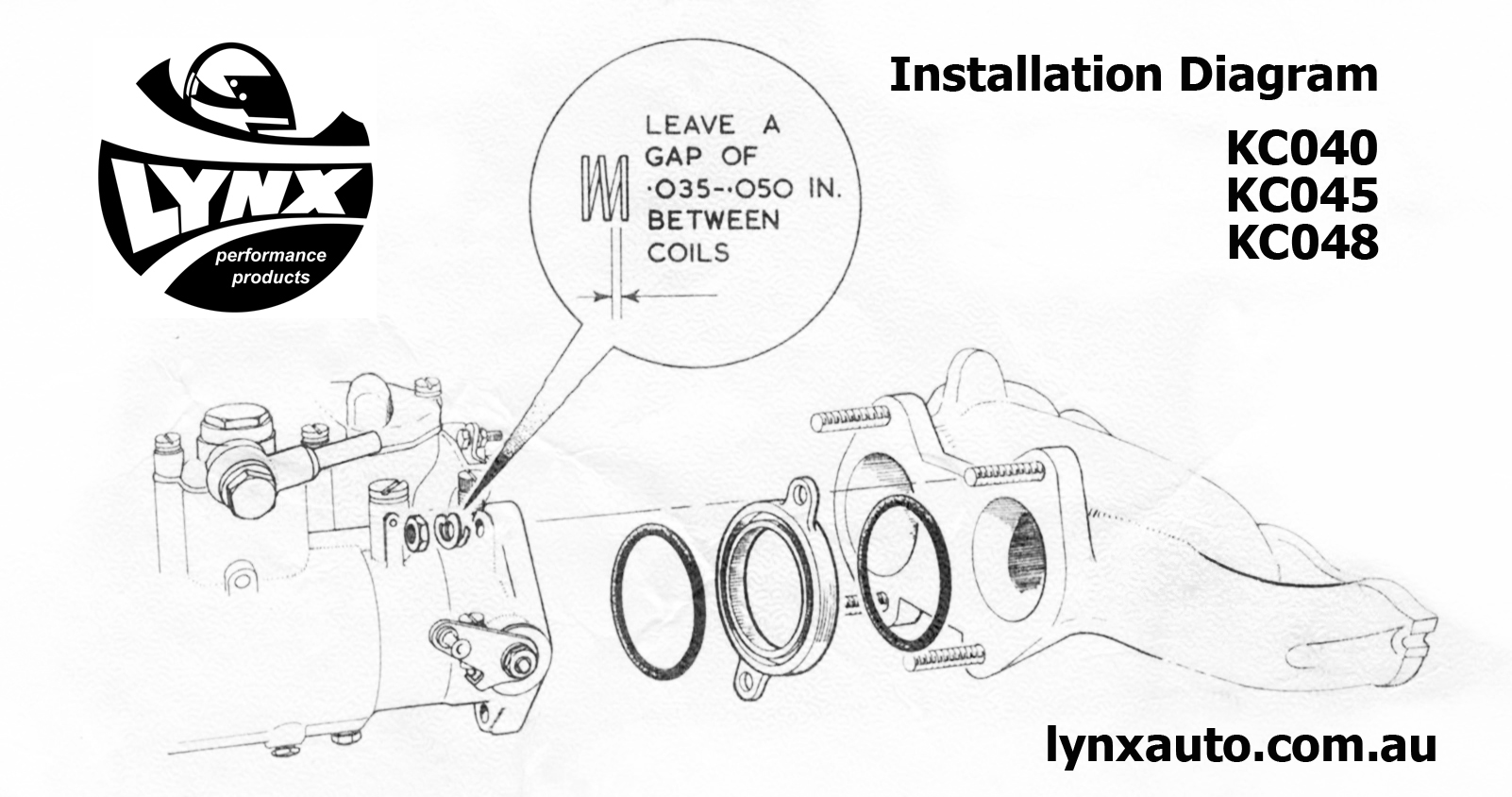

Installing Lynx Soft Mounts (KC040, KC045, KC048)

- Both the manifold surface and carburettor surface should be clean and flat.

- Ensure the carburettor mounting studs are tightened sufficiently into the manifold so as not to work loose. A small amount "loctite" is advisable. Use Lynx KC068 studs.

- Slide the nylon holders with o-rings onto the studs (2 x holders, 4 x o-rings)

- Fit carburettor to manifold studs

- Install thackeray (double coiled) washers to studs

- Fit locking nuts to studs

- Tighten locking nuts and leave a small gap of .035" - .050" (approx 1mm) between the coils of the thackeray washers. If the thackeray washers are over tightened, then you are effectively solid mounting the carburettor. Do not overtighten.

- Visually check the four mounting studs and ensure all locking nuts have wound onto the nylon locking section. If not, do not overtighen. You may have the wrong length studs installed.

- When fitted correctly, you should be able to hold the ram tubes/air filter on the carburettor, and gently move the carburettor freely up and down on the manifold. The thackeray washers will compress/decompress as you do this. If you cannot move the carburettor independant to the manifold, then it is too tight.

Your correctly fitted Lynx KC soft mounts will give many years of trouble free motoring. When performing routine engine servicing, Inspect the condition of the orings and thackeray washers. Over time, and depending on the amount of use, it may be necessary to replace the orings and/or thackeray washers. The part numbers for these are KC053 & KC054